The Challenge:

CO2 sequestration projects are growing in number as the practicality of carbon capture, utilization, and storage (CCUS) to offset greenhouse gas emissions becomes a reality. A key element of any CCUS project is the monitoring, measuring, and verification (MMV) of the CO2 sequestration process for the purpose of ensuring environmental compliance and qualifying tax credits. The CCUS process presents monitoring challenges during transportation and injection, both of which are effectively addressed by technologies and services offered by MSI’s CO2SeQure® carbon management division.

Did you Know?

- Carbon sequestration is the process of decarbonization, or removing atmospheric carbon dioxide, and permanently storing it in solid or liquid form in geologic formations. CCUS are the methods used to prevent carbon dioxide emissions from reaching the atmosphere.

- Greenhouse gas (GHG) emissions are the production of gases that absorb infrared radiation, trapping heat and contributing to climate change. GHG emissions come primarily from burning fossil fuel for transportation, electricity, and heat. Greenhouse gases consist of carbon dioxide (CO2), water vapor (H2O), methane (CH4), and nitrous oxide (N2O).

- CO2 is also used for enhanced oil recovery, whereby CO2 is injected into a subsurface oil reservoir to make the entrapped oil less viscous, which helps the oil move through pore spaces more readily, improving production rates.

- Geophones are sensors used for detecting sound that travels through rock, by measuring ground movements and converting those movements into voltage changes that can be digitized and recorded.

- Distributed Acoustic Sensing optical fiber (DAS) uses interference effects along the fiber caused by changes in strain from acoustic signals to record seismic events in a borehole or along a pipeline, where leaks in the pipeline can be detected and accurately located.

MMV Issues CCUS Operators must Contend with:

- Ensuring the CO2 pipeline operates safely, without leaks.

- Confirming the injected CO2 is staying within the storage formation.

- Monitoring Underground Sources of Drinking Water (USDW), to ensure that no contamination takes place as a consequence of CO2 injection.

- Monitoring levels of CO, CH4, N2O, and CO2 before, during, and after injection operations.

- Monitoring soil gas flux, to ensure no CO2 leaks have gone undetected by other monitoring systems.

- Confirming caprock integrity so that no CO2 escapes.

- Ensuring the injection does not induce seismicity that could potentially damage nearby infrastructure.

Why Conventional 2D/3D Seismic by itself is Inadequate:

Conventional reflection seismic data is usually acquired over the candidate project area to locate faults and assess the structural integrity of the storage reservoir. However, these are static images that fail to address the dynamic issues associated with active CO2 injection.

Why use MicroSeismic CO2SeQure® Fluid Injection Monitoring:

CO2SeQure’s microseismic monitoring before, during, and after injection is a proven technology for:

- Assessing the seismic hazard in the project area

- Mapping faults through the reservoir including those that may not have been imaged by reflection seismic

- Detecting movement of faults and fractures that could compromise caprock integrity

- Detecting small precursor seismic events that can predict larger magnitude induced seismicity

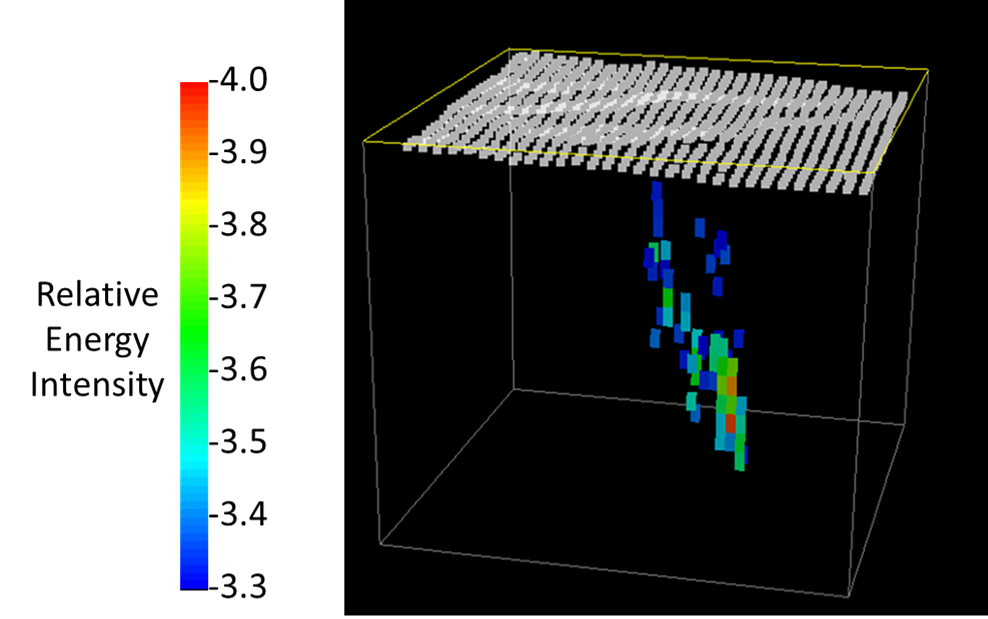

- Tracking the CO2 plume as it grows during the injection process

Over the course of several weeks, MicroSeismic PSET® technology has been shown to be effective in detecting injected CO2 migrating along permeable pathways, and subsequently finding a path to the surface via an abandoned borehole, or a fault connected to the surface. CO2SeQure can provide this critical alert in real-time, to mitigate the risk of atmospheric leaks.

Why is it Cost Effective?

The cost-effective vehicle for monitoring a CCUS project over its lifecycle is MSI’s BuriedArray®, augmented by DAS fiber in a monitor well near the injector well. The BuriedArray comprises multicomponent geophones that are cemented in shallow boreholes at depths less than 300 ft, and intervals of approx. 2,000 ft x 2,000 ft, in array configurations custom-designed for each project.

Each station or DAS interrogator is equipped with telecommunication systems that collect and transmit the data to a central processing facility for real time analysis. The recording and telecommunications hardware for each BuriedArray station is powered by batteries trickle-charged by wind and solar, and function autonomously on a 24/7 basis. The DAS interrogator is situated in a climate-controlled shed at the well site, and uses the grid for power. Annual or semiannual maintenance visits ensure the system functions reliably over the life of the project.

The array will typically be installed before injection begins to measure and calibrate the baseline ambient microseismicity in the area. Once injection begins, the continuous data stream can be analyzed to detect microseismic events that may indicate caprock failure, or slippage on regional faults that could lead to larger magnitude induced seismicity.

A “stoplight system” can be established to automatically notify the operator when events surpassing certain critical levels of magnitude, frequency, or location are identified.

Why use CO2SeQure®?

Critical elements of a successful monitoring program include array design, operational stability, and real time analysis.

MSI has installed and operated more than 75 BuriedArray systems over the last 20 years for a variety of geotechnical objectives, achieving 2,500,000 man-hours with no loss-time incidents.

MSI has the experience and technology to meet CCUS project requirements.

To learn more about CO2SeQure® CCUS Monitoring, please contact:

Stephen Chelette

VP Carbon Strategies

schelette@microseismic.com

281-744-1343